Comprehensive supply market research and feasibility study help leading global escalator company launch new plant in Asia

A leading global escalator manufacturer has a sole manufacturing site in China, supplying 98% of the escalators sold globally. Having a single large production site allowed the company to enjoy the economies of scale and higher production efficiency, but it also meant that they were single sourced so any operational disruption would be of great impact on their business.

ARC Consulting was contracted to conduct a feasibility study to build a second plant in the SEA region with focus countries being Malaysia, Vietnam, Indonesia, Thailand, and Philippines. The feasibility study included evaluations of the market, the local supplier base, the total cost of production (labor and materials) and considerations of any trade risks associated with the particular country.

The opportunity for the company is to build a second production site in SEA that can back-up the site in China, optimize their supply chain in the region, reduce costs and grow the bottom line results. The second plant in the SEA region could be strategic for the company to establish a more competitive position in the region with shorter lead time, lower raw material and labour costs and more advantageous trade conditions.

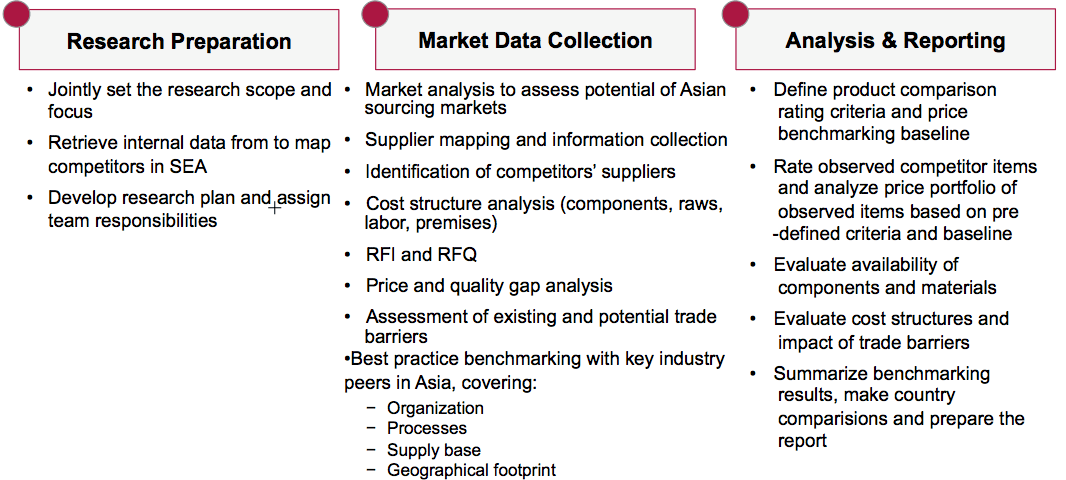

ARC Consulting used a methodical approach based on 3 steps: Research Preparation, Market Data Collection, and Analysis Reporting.

This approach resulted in fact-based data and relevant market research output for each one of the targeted countries (Malaysia, Vietnam, Indonesia, Thailand, and Philippines) that provided key information to make the right decision. Some key information elements provided were: Market characteristics, supplier mapping, local cost structures, price and quality gap analysis and assessment of trade advantages and risks. As the cost and availability of raw materials were key factors for the efficiency and sustainability of the manufacturing operation, a focused cost analysis was performed for key products like hot rolled steel, aluminum, copper, tempered glass, laminated glass, steel plates, cold rolled carbon steel, plastics for the rollers and cast iron. Competitors in the region were also benchmarked for the best practice.

At the end of the project, ARC Consulting presented a comprehensive supply market report with all the key pieces of information that allowed the company to build the business case for building a new escalator assembly factory in the Southeast Asia region.

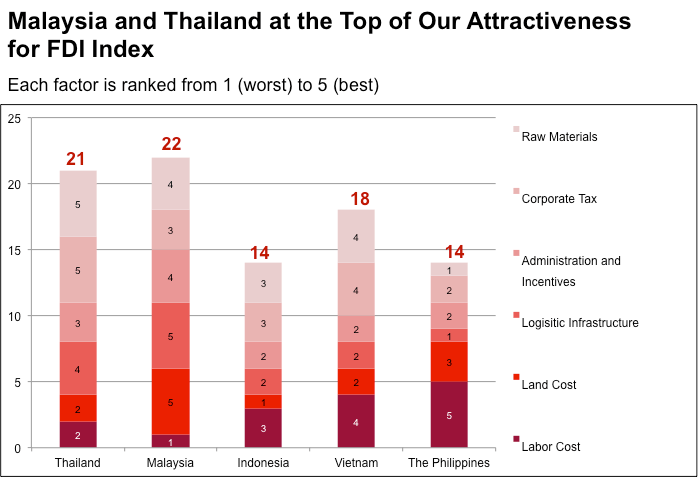

The countries in the SEA region conform ASEAN, Association of South East Asian Nations. The ASEAN region with a population of 628 million and GDP of $2.57 trillion USD is projected to be the 4th largest economy in the world by 2050. The targeted countries represented 82% of the regional GDP and were ranked as follows in Attractiveness for Foreign Direct Investment (FDI): Thailand, Malaysia, Indonesia, Vietnam, and Philippines.

ARC Consulting conducted a thorough overview of each country’s market situation and did a deep-dive into their raw material markets and potential local suppliers of the company. The final result was a good understanding of the strengths and risks of each country with a complete mapping of suppliers highlighting their manufacturing capabilities and the potential product categories they can supply.

After careful analysis of the information, ARC Consulting presented Malaysia and Thailand as first choices to build a new assembly line, Vietnam second, and Indonesia and Philippines as third choices. The information collected and recommendations were fundamental in the final decision-making process of this elevator company.

The project was completed successfully with the following deliverables:

- A comprehensive supply market report with all the key pieces of information that allowed the company to build the business case for building a new escalator assembly factory in the Southeast Asia region.

- A good understanding of the strengths and risks of each country with a complete mapping of suppliers highlighting their manufacturing capabilities and the potential product categories they can supply.

- ARC Consulting presented Malaysia and Thailand as first choices to build a new assembly line, Vietnam second, and Indonesia and Philippines as third choices.

See more about our supply chain management and sourcing consulting services and our experience in the industrial goods and services sector.